The seasons change, and the war drums urge the march. As the year 2025 approaches its final sprint stage, all the staff and workers of the Industrial Solid Waste Resource Utilization Plant of Hebei Xinda Steel Group Co., Ltd. have, with a sense of urgency as if an arrow is on the string and a sense of mission as if a heavy responsibility is on their shoulders, fully sounded the war drum of "Sprint to the End and win the year". All personnel are full of fighting spirit and march with firm steps. They are working tirelessly on the main battlefield of cost reduction and efficiency improvement, and forging ahead with determination on the journey of management innovation. With a series of solid measures, they are promoting lean operation and maximizing efficiency, injecting powerful impetus into the successful completion of the annual targets and tasks.

Steel slag renewal and technological transformation empower

Facing the predicament at the beginning of the year where the screening volume of the steel slag processing workshop did not match the processing volume of the steel slag powder in the bar mill, the factory management leaders immediately conducted on-site research, accurately calculated based on theoretical data, and innovatively implemented a combined improvement plan of "equipment upgrade + system optimization + data empowerment". Through a series of renovations such as installing a quantitative feeder, replacing aged liners, scientifically adjusting the steel bar gradation and loading capacity, and calibrating feeding parameters, the steel slag powder processing capacity of the bar mill has been doubled, laying a solid foundation for efficient and stable production.

To further reduce transportation costs and eliminate safety hazards, the industrial solid waste resource utilization plant has completed the technological transformation project of the conveyor belt for the direct supply rod mill of steel slag powder for screening. Replacing traditional loader transportation with belt transmission not only achieves a significant leap in conveying capacity but also significantly saves costs, ensuring a precise match between belt transmission and the processing capacity of the rod mill.

After the implementation of the two core technological renovations, the industrial solid waste resource utilization plant has continuously explored its internal potential. By coordinating fleets, replacing electric forklifts, and optimizing the feeding process, it ensures the efficient matching of the preceding and subsequent procedures. A series of measures have reduced the processing cost per ton of product by 5.15 yuan, achieving remarkable results in cost reduction and efficiency improvement.

Silicon and aluminum consumption control for energy saving and efficiency improvement

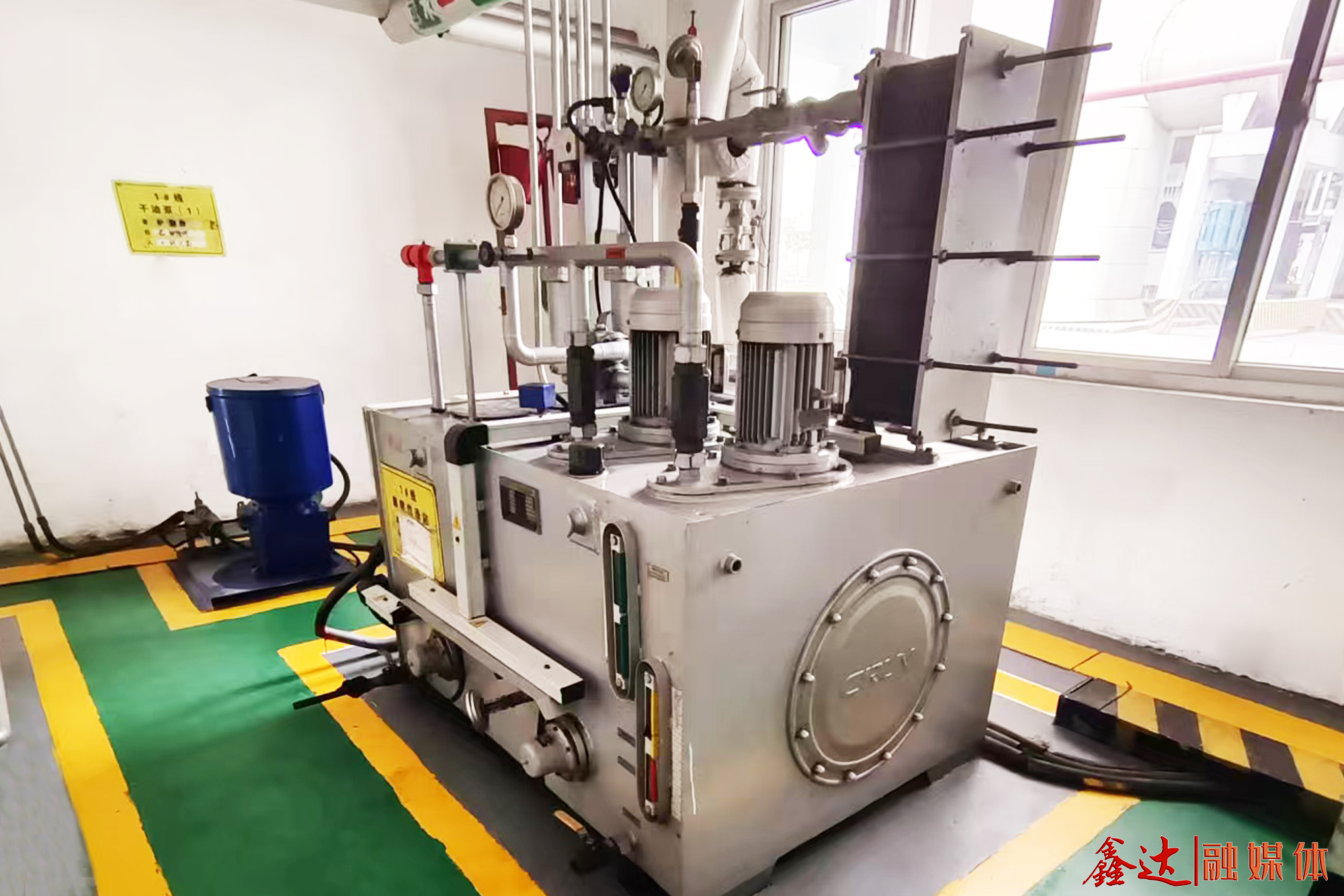

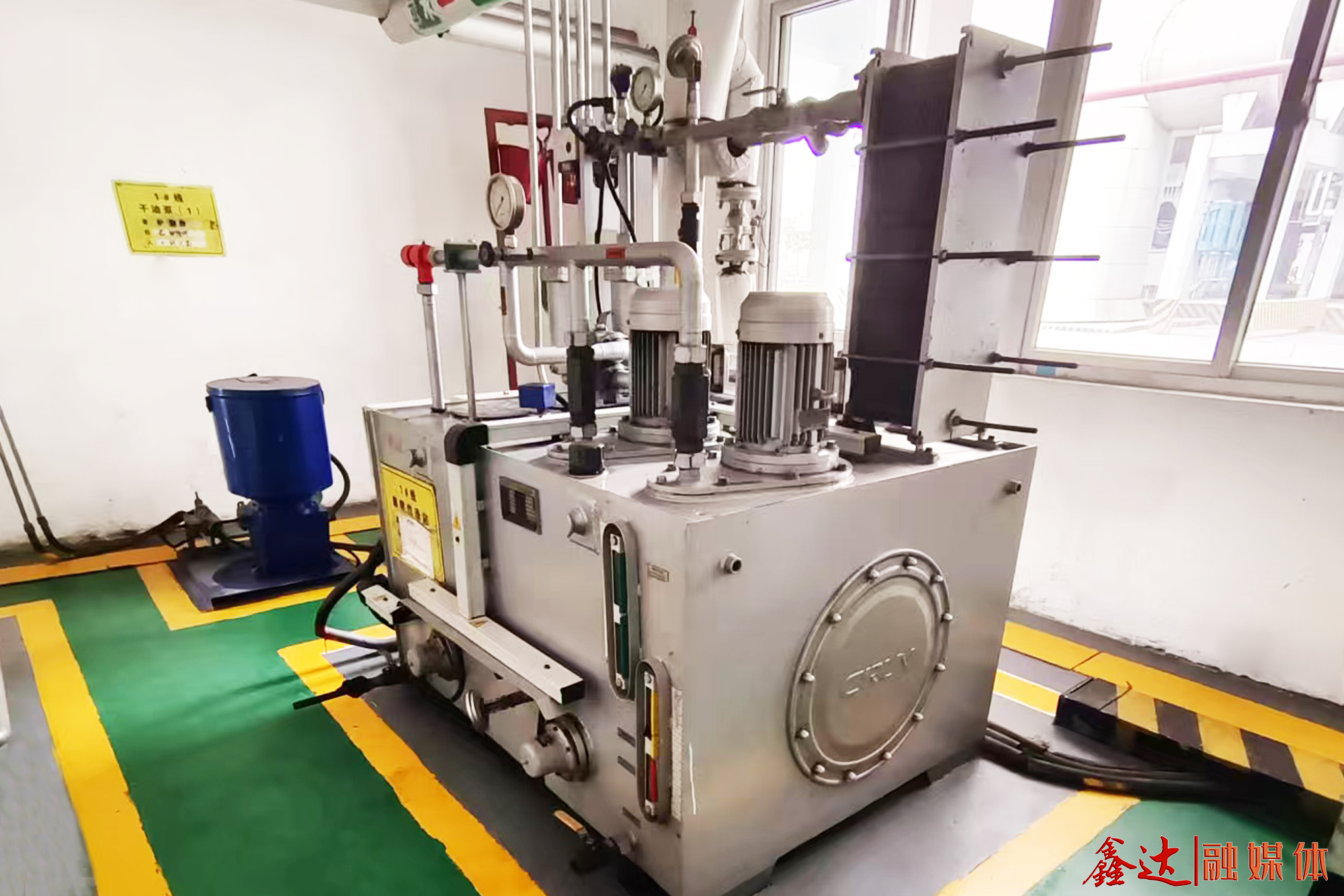

The silicon, aluminum and barium workshop has focused on the pain point of high power consumption per ton of product and taken multiple measures to launch a tough battle for energy conservation and consumption reduction. Implement peak shaving and off-peak electricity usage plans, and work with supply departments to purchase refractory materials with high refractoriness and low thermal conductivity for the furnace body, thereby extending the service life of medium-frequency furnaces. Strengthen skills training, precisely control the melting temperature and heating time of silicon, aluminum and iron, and improve the efficiency of a single furnace. Optimize the cooling circulation water system, strictly control the temperature difference of the cooling water circulation, regularly clean the thyristor cooling water tank, and reduce equipment failures. Dynamically adjust the operation of the water pump according to the temperature changes to reduce reactive power consumption. During the peak shaving production period in the first quarter, the power consumption per ton of silicon-aluminum-iron products decreased, with a cumulative cost reduction of 35,809 yuan, achieving remarkable energy-saving results.

The gas consumption is greatly reduced due to the precise control of the briquettes

As a key department consuming natural gas, the briquetting workshop has a significant task of cost reduction. In 2025, the factory department will take the lead in implementing systematic control, formulate a performance management mechanism, and fully mobilize the enthusiasm of employees. Establish a regular inspection and replacement system for the dimensions of press molds and push blocks, and keep the return volume of press blocks within 5%. Rebuild the briquetting production control system, incorporate parameters such as particle steel, natural gas adjustment and measurement, and material temperature into the central control room for unified management. Under the premise of meeting the pressing temperature, with natural gas consumption as the core objective, dynamically adjust the feeding amount, rotary kiln speed, and the opening degree of the natural gas valve. Based on the characteristics of raw materials, formulate quality and arrival acceptance standards to reduce the adverse effects of raw materials on natural gas consumption, dust collection volume, return material volume and lumping rate. Benchmark against advanced enterprises to learn from their experiences, explore the process control indicators for low natural gas consumption, and unify the operation standards for three shifts. Carry out the renovation of the process dust collection system and the environmental dust collection system to ensure the stable operation of the equipment. In the first half of the year, the average natural gas consumption per unit in the briquetting workshop decreased by 1.4 cubic meters, and the cumulative cost savings reached 880,544 yuan.

All personnel charge ahead to achieve a decisive victory and conclude the event

The industrial solid waste resource utilization treatment plant actively responds to the company's cost reduction and efficiency improvement strategy. It refines the cost reduction plan by using Gantt charts and delves into the root causes of problems with the help of fishbone charts. After identifying the key issues, it implements targeted measures. Since 2025, gas consumption has continued to decline, and cost control has achieved remarkable results. Entering the final sprint stage of December, the industrial solid waste resource utilization plant has set its core goal of reducing the cost per ton of steel. It has broken down the task to each workshop and ensured that the cost reduction task takes root through a full-process mechanism that includes target decomposition, responsibility assignment to individuals, supervision in a closed loop, and timely feedback.

Since the implementation of the company's production and operation responsibility system, the industrial solid waste resource treatment plant has comprehensively carried out self-examination and self-correction as well as optimization and improvement in accordance with the new standards and requirements. During the crucial period of the final sprint, all the staff and workers have united their efforts and worked in coordination. The front-line workshops have been striving hard to catch up with the schedule, technical experts have been deeply rooted in the site to solve problems, and the logistics support has been making every effort to make up for the shortcomings. With the firm belief of a decisive victory, a strong atmosphere of unity and determination to overcome difficulties has been formed, and a final charge has been launched towards the annual goals.

The journey lies beneath our feet. Only with firm steps can we go far. The future can only be achieved by striving forward; with perseverance and unwavering commitment, glory will eventually be seen. Hebei Xinda Steel Group Co., Ltd. will delve deeply into green smelting to activate low-carbon momentum, refine lean production to build a quality Great Wall, cultivate a fertile ground for talents to accumulate development potential, and continuously promote innovation to break through and improve quality and efficiency. With the craftsmanship of meticulously crafting every inch of time, we gather the strength for the decisive battle. With the posture as high as the rising sun, we bravely charge forward to win the battlefield. With the perseverance of long-term efforts, we win the in-depth battle of operation and control. United as one, we spare no effort to strive for all the goals and tasks of the year, and work hard to write a new answer sheet for the company's green and high-quality development path and compose a more brilliant chapter of The Times!

Email

Email Email

Email