The year 2025 marks a crucial period for Hebei Xinda Steel Group Co., Ltd. as it intensifies its efforts to transform and upgrade, and resolutely moves towards high-quality development. As the "source guarantee station" of the group's production chain, the Raw Materials Plant, with the main line of "stabilizing production, improving quality, reducing costs, and increasing efficiency", has united all its staff and officers to forge ahead with determination. They have achieved solid results in key areas such as stable production and supply, technological innovation, cost reduction and efficiency improvement, as well as safety and environmental protection. As the year draws to a close, the group's clarion call for a "final sprint to secure the year's goals" has been sounded. All colleagues at the Raw Materials Plant are now working with a sense of urgency and a strong sense of responsibility, fully committed and striving hard to lay a solid foundation at the source for the group to achieve its annual targets.

Over the past year, the raw material factory has consistently adhered to the operational philosophy of "safety as the foundation, stability as the priority, quality as the core, and efficiency as the benchmark". It has continuously made efforts in strengthening management, driving technological innovation, and exploring potential for increased efficiency, presenting the company with a remarkable and impressive report card.

Stable production and supply safeguard the bottom line; production and operation are steadily advancing.

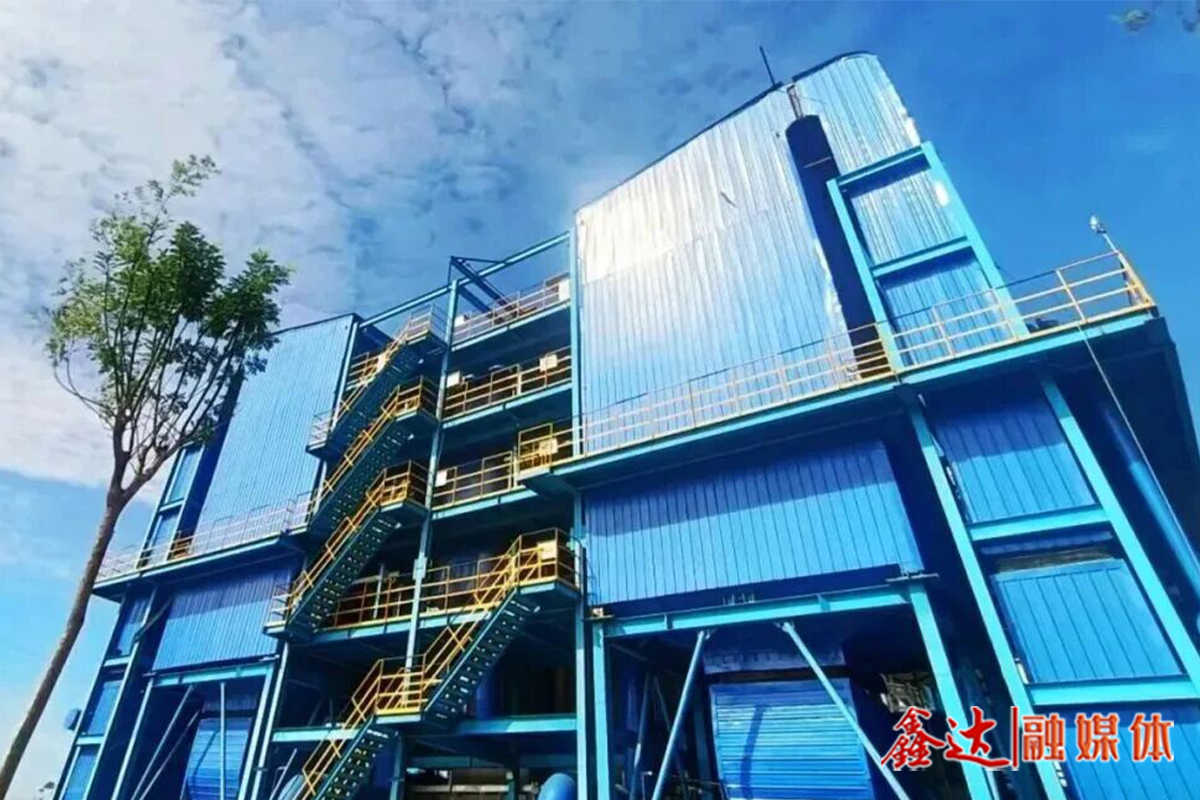

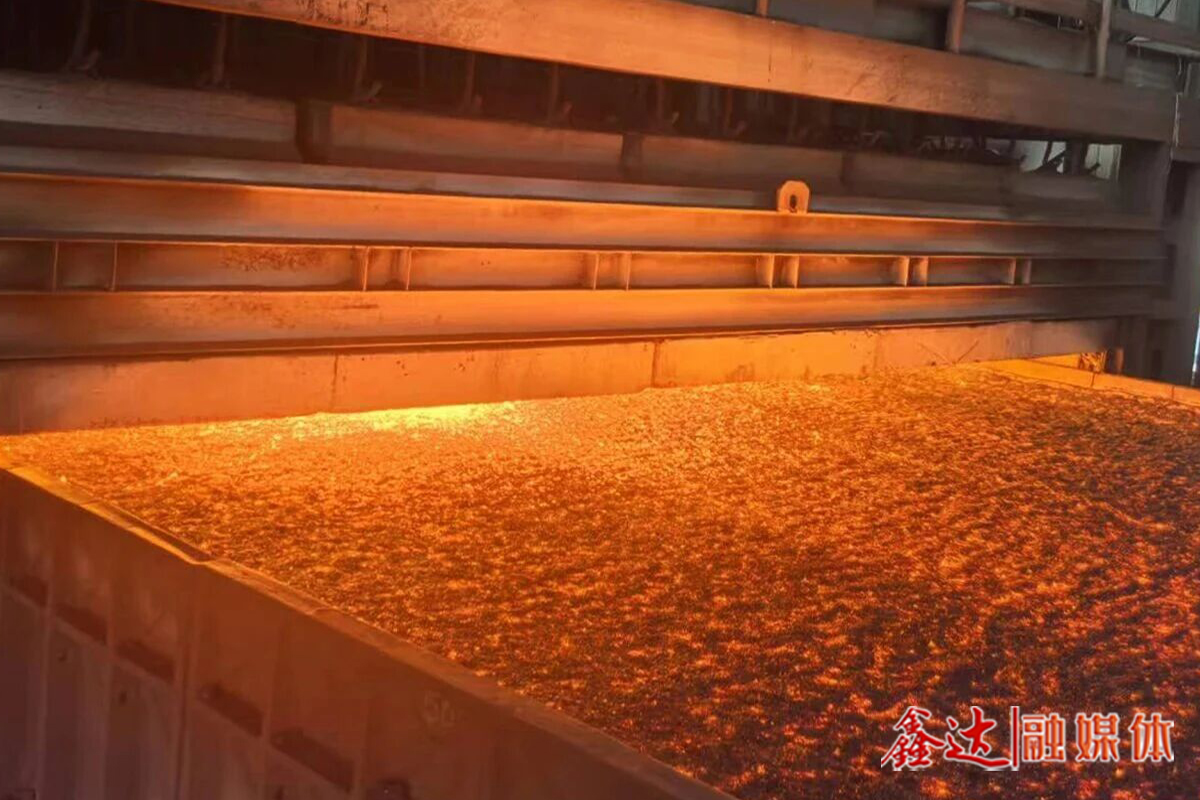

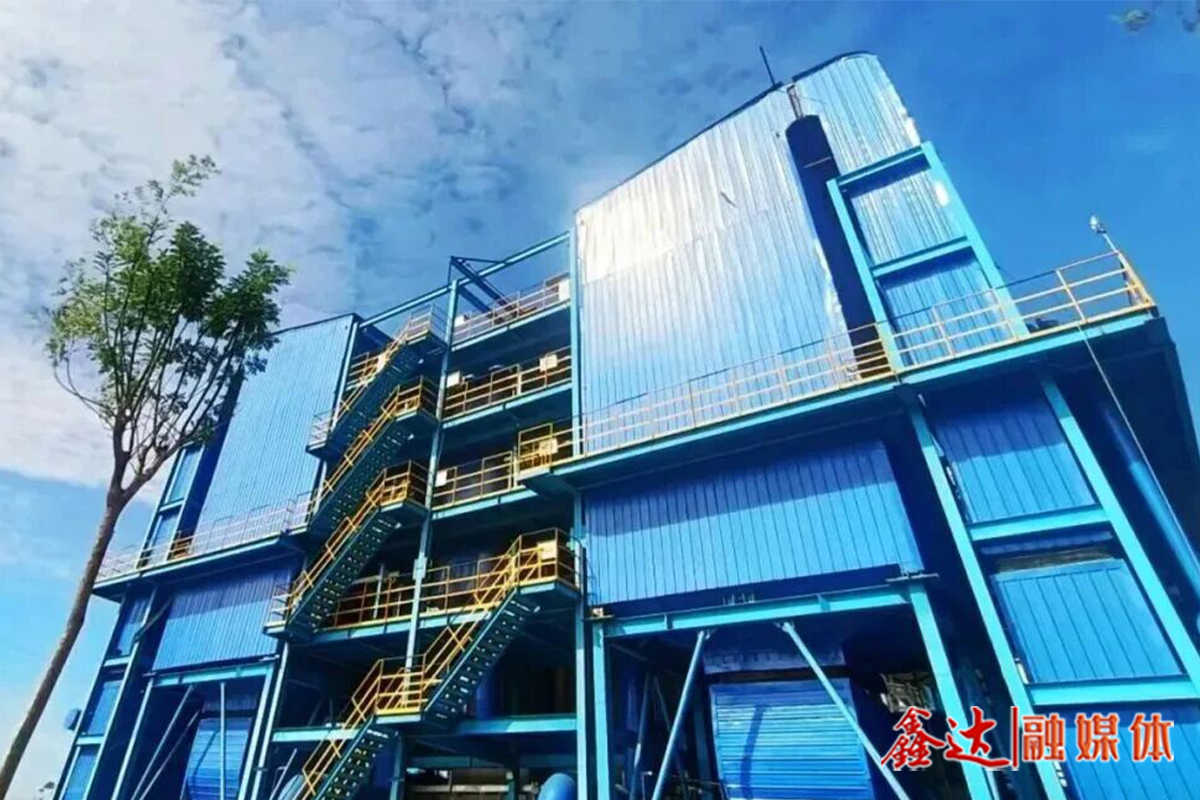

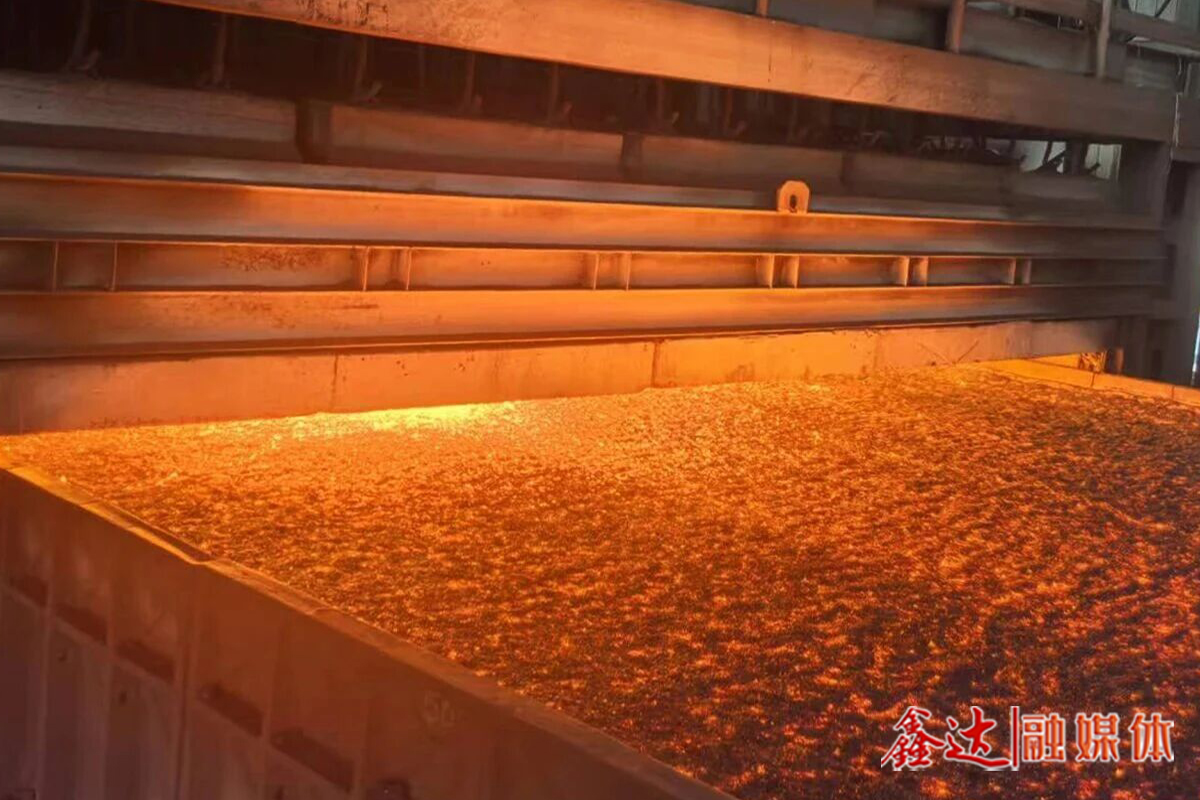

Facing the dual challenges of a complex and volatile external environment and internal improvement, the raw material plant scientifically organized production scheduling, continuously optimized process parameters, strengthened equipment inspection and predictive maintenance, ensuring the stable operation of the entire production chain. Through the implementation of refined operation management and process control, the stability rate of key processes has significantly improved, providing a solid and reliable raw material guarantee for downstream processes and firmly maintaining the stability bottom line of the production source.

Innovation-driven growth in technology and further improvement in quality control reach new heights.

The raw material plant has always regarded technological innovation as the core engine to solve development problems and enhance core competitiveness. It has focused on three major directions: optimizing raw material structure, upgrading process routes, and intelligent transformation, and has precisely exerted efforts. It has successfully implemented and promoted a number of minor improvements and rationalization suggestions, effectively enhancing the advancement and stability of process indicators. At the same time, it has continuously improved the full-chain quality control system. By strengthening source control, process supervision, and terminal analysis, the quality indicators of major raw materials have steadily improved, and the consistency of products has been highly recognized by downstream units, laying a solid foundation for the quality upgrade of the group's products.

Cost reduction and efficiency improvement have tapped potential, and business performance has steadily improved.

The raw material plant has firmly established the cost control concept of "living frugally and well", and has implemented cost reduction and efficiency improvement throughout the entire production and operation process. On the one hand, it strictly controls material and energy consumption, and through measures such as optimizing operation processes, eliminating leaks and spills, deepening the reuse of old materials, and promoting the stepwise utilization of energy, the main unit consumption indicators have been effectively reduced year-on-year. On the other hand, it has deepened benchmarking management, set its sights on the advanced level of the industry and the best historical performance, accurately identified the gaps, formulated rectification plans, and targeted breakthroughs in the pain points and difficulties of cost control. At the same time, it has actively explored stable application solutions for economical raw material resources, and under the premise of strictly adhering to the quality bottom line, it has opened up a new path for reducing the comprehensive production cost.

Safety and environmental protection build a barrier, making the green development background more prominent.

The raw material plant has always adhered to the core principle of "life first, safety first", and deeply practiced the concept of lean safety management. By strengthening safety training, improving emergency response plans, and intensifying the inspection of potential hazards, it achieved a "zero accident, zero casualty" record throughout the year. It only took three months to make a splendid transformation in safety management from "up to standard" to "excellent".

In terms of environmental protection and governance, we have been unwaveringly committed to the path of ecological priority and green development. We have continuously increased investment in environmental protection, successfully applying advanced treatment technologies such as catalytic oxidation. This has not only broken the conventional perception that environmental protection requires high investment and low returns but also explored a new green development path of "governance promoting energy conservation and energy conservation creating benefits". The environmental appearance of the factory area has been continuously improved, demonstrating Xinda's responsibility and commitment.

The decisive moment is now, and we must unite our efforts to reach the finish line! We are now in the final sprint stage of the year's work. All the staff and workers of the raw material factory are adopting an aggressive attitude of "not sitting idle, not waiting, and not being slow", implementing precise measures and strictly enforcing them, determined to achieve a full success in the year's work.

Anchor the core goals and layer by layer, solidify responsibilities.

The raw material plant has clearly defined the core goals for the final sprint stage: under the premise of resolutely maintaining a "zero accident" bottom line in terms of safety and environmental protection, ensure efficient and stable production operation, a steady improvement in quality indicators, and cost control reaching the optimal level of the annual budget, and fully exceed the various core tasks assigned by the group. All departments and processes should promptly break down the goals to individual positions and assign responsibilities to individuals, building a full-scale sprint pattern where "everyone has an indicator on their shoulders and every position shows responsibility."

Refine the measures for tackling tough issues and focus on targeted breakthroughs.

Centering on the sprint goal, the raw material plant has formulated five major breakthrough measures: First, further optimize production organization, implement the "extreme stability" production mode, strengthen internal and external coordination and linkage, improve emergency plans for extreme weather, market fluctuations and other unexpected situations, and ensure the safety and smoothness of the entire supply chain. Second, further tighten quality control, launch the "zero defect quality" special action, conduct full-process precise monitoring and data analysis of raw materials, intermediate products and final products entering the factory, respond to abnormal situations immediately and handle them quickly, and resolutely safeguard the quality lifeline. Third, further deepen cost reduction and efficiency improvement, launch the "100-day cost reduction sprint" campaign, conduct a comprehensive review and in-depth analysis of all cost and expense items, strictly control non-production expenditures, and deeply explore the potential for efficiency improvement in each link. Fourth, further strengthen safety and environmental protection, carry out a special winter safety and environmental protection inspection, focus on strengthening the control of key links such as fire prevention, freeze prevention, slip prevention and poisoning prevention, increase the frequency and intensity of inspections, ensure that environmental protection facilities operate in the best condition at all times, and eliminate any slack and complacent thinking. Fifth, further upgrade equipment support, strengthen the special care management of key equipment, carry out preventive maintenance during production breaks, and fully reserve spare parts to provide solid and reliable hardware support for the sprint to the finish line.

Conclusion

When the efforts of all are pooled, no task is too difficult to accomplish; when the wisdom of all is combined, no goal is too far to reach. Looking back at 2025, the raw material factory has made solid progress and achieved fruitful results. As we charge towards the final stretch, the raw material factory is brimming with confidence and full of fighting spirit. All the staff and workers will channel all their energy, wisdom and sweat into the year-end battle with the tenacity of "not giving up until the goal is reached" and the perseverance of "holding fast to the mountain and never letting go". We will resolutely win the "final sprint and decisive victory for the year" campaign, contribute the raw material factory's mighty force to the successful completion of the annual tasks and goals, and greet the new chapter with outstanding achievements!

Email

Email Email

Email