Hard work for early spring, full bow and then set out

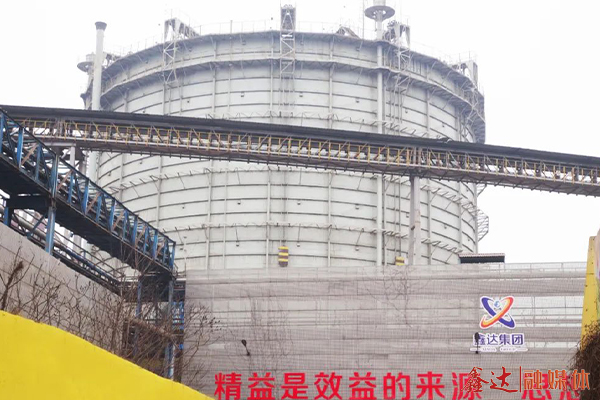

Hebei Xinda Iron and Steel Group Co., Ltd. energy power plant

Grab the early spring golden period

Actively promote all energy production work

Strive to provide energy support for smelting casting and rolling

Energy power plant has always maintained the "start is a decisive battle, start to sprint" attitude of struggle, gather all staff morale, do a good job in the production organization, sprint the first quarter "start", and strive to achieve a full year ". In terms of energy management, increase power management efforts, continue to implement peak-avoidance measures on valley power consumption, in January and February 2024, the implementation of peak-avoidance on valley electricity saving about 5.766 million yuan; Through the optimization and improvement of steelmaking production operation, gas tank inlet connection adjustment, converter gas tank position control, gas discharge inspection control and other aspects, the converter gas recovery volume and recovery efficiency are improved. From January to February 2024, the converter gas recovery value is increased by 8.34m³/t compared with the planned value, and the efficiency is about 2.067 million yuan.

Energy saved

In the first quarter, the energy and power plant focused on energy consumption, focused on energy conservation and consumption reduction, focused on unit energy consumption indicators, energy conservation and environmental protection indicators, strengthened operation management, carried out a comprehensive survey of unit energy consumption, fully carried out technical research to reduce gas consumption and plant electricity consumption rate, and continued to optimize unit performance indicators.

In order to continuously reduce the energy consumption of one generator set in 2023, specific measures are formulated to promote the continuous optimization of the power consumption of the plant: with refined operation guidance, key positions such as boiler and turbine personnel are trained in power saving knowledge and practical operation ability to reduce the self-use power rate; Adhere to the activities of exploring potential for the standard, hold regular meetings of the branch factory every week, sum up experience, compare the standard to find the difference, and ensure that various energy-saving measures are implemented in place; In the process operation mode, for the power consumption of large equipment, such as circulation pump, feed pump, fan analysis and monitoring. When the load is low, stop the operation of one circulating pump, and when two circulating pumps need to be started to recover rubber balls, the night valley time is used to start to save electricity. Timely operation adjustment, standardized and reasonable use of frequency conversion equipment.

Through optimized management, the plant electricity consumption rate of the unit in January-February 2024 decreased by 0.57% and 0.48% respectively, and the electricity consumption in January-February reached 374,700 KWH.

Knotted gas

Converter gas is one of the byproducts of steelmaking process. Through efficient recovery and rational utilization, it can reduce the energy consumption of converter process, improve the recovery level of steelmaking process, and reduce the emission of waste gas, effectively control air pollution, and realize clean production. The energy and power plant firmly adheres to the goal of "improving the recovery amount of converter gas" and constantly challenges, focusing on the aspects of operation system, data verification, production coordination, etc., to ensure that the gas recovery time is maximized and the balanced utilization of gas is promoted.

In view of the data of the minimum 130m³/t converter gas recovery in 2023, the Energy Dispatching Department of the Energy and Power Plant actively searched for the reasons and formulated measures to steadily increase the amount of gas recovery. Check the gas leakage situation with the branch plant, and tightly close and disperse; When the inlet of the gas tank is connected, the gas recovery capacity is obviously improved. When the converter is recycled at the same time, the double tank should be recycled to avoid energy waste, and the gas tank should be kept running low at all times to achieve full gas recovery. Strictly implement the assessment system, hold an analysis meeting on the receivables, implement the responsible person, and formulate corresponding measures; According to the length of each furnace blowing time, timely adjust the recovery time and recovery period to ensure the maximum recovery of each furnace gas; Increase the process discipline inspection and spot inspection of gas recovery equipment, regularly check the converter gas pipeline, and eliminate the waste of gas, steam and other energy caused by equipment failure.

Energy and power plant adhere to the system overall planning, the pursuit of ultimate energy efficiency, continuous optimization of process parameters, fine control of each link, and strive to achieve all gas consumption. Through the above measures, the efficient operation of the converter gas recovery equipment is ensured, which provides a strong guarantee for the converter gas recovery. In January-February 2024, the recovery of ton steel converter gas reached 138.34m³.

"Benefit" from repairs

The energy and power plant adheres to the rehabilitation of old and waste as a normal work, vigorously advocates the rehabilitation of old and waste, and reduces maintenance costs. From January to February 2024, A total of more than 10 items have been completed, such as the repair of a gas tank pressure machine, the repair of the water treatment section slag pump, the repair of the gas regulating valve of the power generation boiler, the repair of the minimum flow valve of the power generation feed pump, the repair of the screen of the sub-critical power generation fine treatment of silicone root monitor, the repair of the waste heat excitation regulator, and the repair of the planetary gear reducer of the cooling tower of the air compressor station.

The opening is the decisive battle, the battle is the attack, the thought of "drawing the bow", the production of "rivet foot strength". Energy power plant is moving forward toward the goal with a hot and hot atmosphere. In 2024, the energy and power plant will continue to climb to the "high", to the "new" and to the "forward", do a full range of energy supply work, take new steps in reducing costs and increasing efficiency, ensuring supply and demand, and climb new heights!

Email

Email Email

Email