In order to actively implement the concept of green development and build an intelligent and efficient modern steel factory, Hebei Xinda Steel Group Co., Ltd. has launched a special campaign called "Environmental Improvement, Beautification, Lighting and Greening Campaign Month". This action is not only a comprehensive renewal of the factory area's appearance, but also an innovative practice of the group deeply integrating lean management into the production ecosystem, injecting new vitality into the sustainable development of the enterprise.

01

Lean as the guideline

Build an all-round environmental governance system

In this offensive operation, the Lean Management Department played a key leading role and innovatively introduced the "two-dimensional drive" governance model, providing a solid guarantee for the environmental improvement work.

The 6S governance is closed-loop. Taking the work section as the unit, a dynamic ledger of "self-examination - rectification - handover" is carefully constructed, and the four major functional departments take turns to carry out weekly joint inspections. Led by the first-level supervisor and closely coordinated by the two levels of the science and engineering section, the mechanism of "problem exposure → key listing → assistance and supervision" is utilized to ensure that all kinds of problems existing on the site can be "cleared daily and settled weekly", making on-site management more standardized and efficient and creating a favorable environment for production and operation.

Refined progress control. The pioneering "three-color progress board" has become a major highlight in the rectification of progress management. The green light for greening management is on every Wednesday, the yellow light for beautification and lighting is on every Friday, and the red light for the weekly joint inspection results is on every Monday. The progress of each task is presented visually through colors. The Lean Management Department has assigned dedicated personnel to analyze and statistically analyze relevant data, closely monitor the on-site improvement situation every day, promptly solve on-site problems, and effectively promote the smooth progress of the rectification work.

02

Green Dynamic Steel City

Innovative measures activate the ecological environment of the factory area

Two innovative measures have continuously injected vitality and vigor into the factory area. "Greenery wherever possible" skillfully weaves a splendid tapestry. We actively promote the "One Person, One Flower, One Pot, One Scene" mass campaign, fully mobilizing the enthusiasm and creativity of all employees. During the breakthrough month, 2,800 square meters of greenery were successfully expanded and 640 trees were planted, allowing steel and greenery to coexist in harmony and making the factory area brim with lush greenery everywhere.

The "either hard or green" approach has been a key breakthrough. All the branch factories have taken action one after another. The raw material factory has removed the abandoned fences and carefully created a three-dimensional flower wall. The industrial solid waste resource utilization plant plants fruit trees, turning the factory area into an orchard. The ironmaking plant carried out in-depth treatment of the drainage ditches to solve the long-standing problem. The total area of road renovation in the entire factory exceeds 10,000 square meters. In addition, 2,800 square meters of new green space, 10,000 square meters of new hardened space, and 13,600 square meters of wall facility painting have been completed, transforming the steel factory area into a green home.

03

rejuvenated and reborn

The visual upgrade highlights the charm of intelligent manufacturing

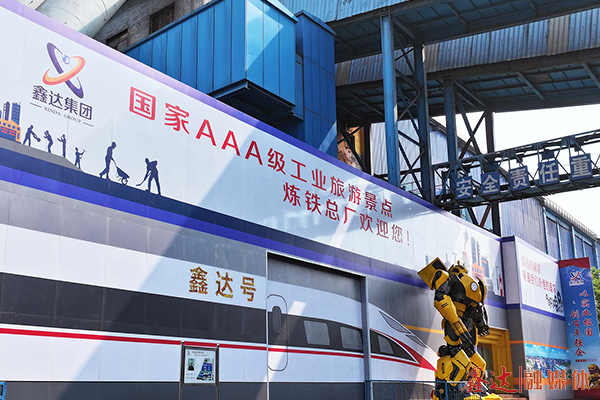

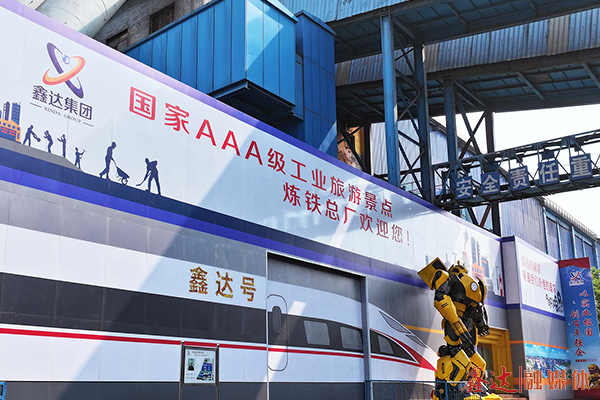

The Lean Management Department has taken visual management as an important breakthrough point for environmental improvement, implemented the "Renewal Project", and redefined the industrial background of the factory area. Organize forces to paint 13,600 square meters of old walls and repair 65 damaged facilities, giving the factory area a brand-new look. The visiting point of the Steel Rolling General Factory has taken on a brand-new look with the addition of multiple landscape features, adding vitality and dynamism to the factory area. The signboard at the reception point of the ironmaking plant made its debut in the shape of a brand-new bullet train, symbolizing that Xinda is forging ahead like a bullet train, demonstrating strong development momentum.

04

All staff are working hard to overcome difficulties

Gather powerful synergy for green transformation

Environmental improvement is not a superficial effort; rather, it is about enabling factories to truly achieve green development through lean approaches. This concept inspires all Xinda people to keep moving forward. More than ten supervisors carefully upload the actual situation of the rectification every day and provide real-time feedback on the progress of the work. Master Wang, the road chief of the raw material factory, insisted on filming the progress of the dust removal net update in the early hours of the morning. He said, "Every change must be visible." The 216 section of the raw Materials Plant is actively carrying out on-site continuous improvement work. Zhang Zhijia, an employee of the section, said with confidence, "We will turn this place into the most beautiful sintering production line." They are interpreting their pursuit of a green production environment with their practical actions. The functional departments have also launched an "office area revolution". The technical department has carried out a "decluttering" of the drawings and materials to make the office environment cleaner and more orderly. The Equipment Department has transformed the spare parts warehouse into a "model room", setting a benchmark for standardized management. The activity of Posting standard photos on the wall in the office area has been carried out in a lively and colorful manner. With a standard photo Posting rate of over 93%, the 6S management level in the office area has been significantly improved.

Green fills the steel city with a new look, and lean empowers the future. This breakthrough month event is a new picture of industrial ecology drawn by Xinda with lean as the ink and green as the brush, and it is a vivid practical textbook of the lean concept. From the daily progress tracking by supervisors to the early morning records of changes by front-line employees, the joint efforts of all staff to solve problems prove that steel and nature are never in opposition, and that industrial civilization and ecological civilization could have harmonized. Standing at a new starting point, Xinda is shouldering the responsibility of "I will surely contribute to success", playing the powerful note of "Green Steel Enterprise, Leading the future" in the chord between industrial civilization and ecological civilization, and is constantly striving towards the goal of building a modern steel enterprise that is green, intelligent and efficient!

Email

Email Email

Email