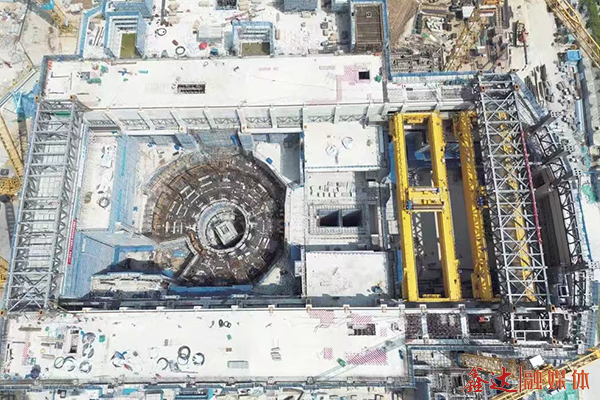

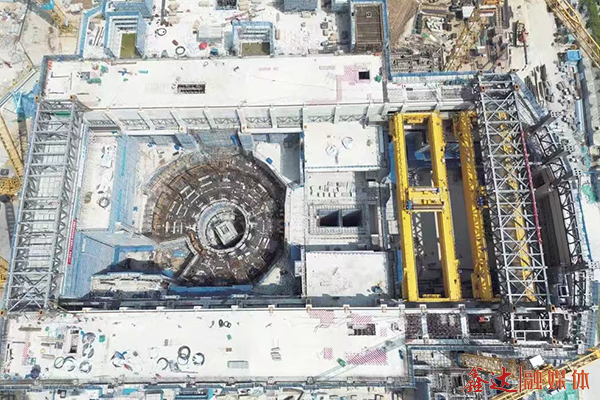

On May 1st, in the comprehensive research facility park for the key systems of the fusion reactor main unit in Hefei, Anhui Province, a project that will rewrite the history of human energy is being implemented in full swing. With the slow positioning of four giant crane main beams, each 52 meters long and weighing 400 tons, the engineering assembly of the world's first compact fusion energy experimental device (BEST) was officially launched, taking a crucial step towards achieving the strategic goal of "the world's first fusion energy power generation".

The CHSN01 ultra-low temperature high-strength and high-toughness non-magnetic steel (referred to as CHSN01 steel), which is independently developed in China, will provide indispensable support for the powerful beating of this 6,000-ton fusion reactor "heart". This new stainless steel material, jointly developed and researched by the Central Iron and Steel Research Institute Co., LTD. (referred to as Central Iron and Steel Research Institute) under China Iron & Steel Research Group, the Institute of Plasma Physics of the Chinese Academy of Sciences (referred to as Plasma Institute), and the Institute of Physical and Chemical Technology, will be transformed into a 500-ton armor and coil box linear segment component, embedded in the most core superconducting magnet system of the BEST device. Facing the extreme cold test of minus 268.95 degrees Celsius (4.2K), we have lifted up the great dream of our country's "artificial sun" and contributed a "Chinese solution" to the clean energy revolution of mankind.

The picture shows the assembly site of China's BEST fusion device. CHSN01 steel will support the core structure of this "artificial sun" superconducting magnet system. (Photo provided by Institute of Plasma Physics, Chinese Academy of Sciences)

Research and development breakthrough

Solve the world-class problem of the coordinated regulation of material strength and toughness at ultra-low temperatures

Controlled nuclear fusion is known as the "artificial sun", but to master this "sun", the first step is to overcome the material challenge. In response to the national strategic demands, the Central Iron and Steel Research Institute, in collaboration with the Institute of Plasma Physics and other units, jointly established an innovation team. They ventured into uncharted territories and, in November 2021, joined hands with alliance units to overcome difficulties. Based on the team's rich scientific research achievements in ultra-low temperature materials, It took only two years to successfully solve the world-class problem of the coordinated regulation of material strength and toughness in an extremely low-temperature environment of minus 268.95 degrees Celsius.

It can be said that the research and development story of CHSN01 steel is a vivid microcosm of the journey of young steel researchers in China to achieve high-level self-reliance and self-strengthening in science and technology. On July 23, 2021, when the project was just launched, Dr. Wang Changjun, the team leader who was only 38 years old, took on the heavy responsibility and led this young innovative team to charge forward towards solving world-class problems. Facing this world-class challenge, we can only feel our way forward, try bit by bit, and constantly iterate the ingredients and optimize the manufacturing process. Professor Yang Zhiyong, an expert of the team, recalled the difficult situation at that time with deep emotions.

On December 8, 2021, the key technology research and development was officially launched. On August 30, 2022, the first batch of pre-research components passed the review, verifying the feasibility of the core design concept. On March 4, 2023, the project made an important phased progress and initiated the industrial trial production of 1:1 prototype parts. On August 6, 2023, the prototype successfully passed the strict review, and all material performance indicators fully met the design requirements, demonstrating potential for engineering application. The constituent units of the research and development alliance have also expanded from the initial six to 17 units covering industry, academia, research, inspection and application. On this basis, on November 16, 2023, the Joint Laboratory for the Research and Development of High-End Metal Materials for Fusion was officially established at the Energy Research Institute of Hefei National Science Center. When it comes to the key milestones in the research and development process, Dr. Wang Changjun and Dr. Qin Jinggang can recite them off the top of their heads.

The picture shows a group photo of the guests attending the "New Generation of High-End Metal Materials for Fusion Engineering" forum and the "Research and Development Progress of 4.2K High-Strength and High-Toughness Stainless Steel" seminar on March 4, 2023. (Photo provided by Central Iron & Steel Research Institute)

The leap from the laboratory to industrialization is equally difficult. In order to achieve batch production of over 100 tons, the Central Iron and Steel Research Institute has adopted a "small core, large collaboration" model, in collaboration with the Institute of Plasma Physics and Jiuli Special Materials, to break through the technical bottleneck of high-precision inner round and outer square armor rolling. The dimensional accuracy error of the armor does not exceed ±0.02 millimeters. In collaboration with Panzhihua Iron and Steel Group and Great Wall Special Steel, we have successfully completed the entire production process for a series of hot-rolled plates with a thickness of less than 90 millimeters. In collaboration with Shanghai Electric, Shangzhong Casting and Forging has overcome the production challenges of 6-ton large forgings and achieved "zero defects" in 5,000-millimeter-long large forgings. After more than three years of perseverance and hard work, the "first of its kind in China" has finally emerged as a butterfly. On December 7, 2024, the "CHSN01" trademark was officially registered, marking that the research and development achievement has officially entered the stage of engineering application and industrial promotion, and has rapidly achieved mass production, enabling China to make its first leap from "following" to "leading" in the field of nuclear fusion materials.

Performance leap

Set a new international benchmark for ultra-low temperature nuclear fusion materials

In an extremely cold environment of minus 268.95 degrees Celsius, ordinary steel is as brittle as glass. Facing difficulties, the team broke through the limit of low-temperature structural materials for nuclear fusion, achieving a qualitative leap in the performance indicators of CHSN01 steel and setting a new international benchmark: In an extremely cold environment of minus 268.95 degrees Celsius, the yield strength of the CHSN01 armor exceeded 1,500 megapascals, equivalent to an area the size of a fingernail being able to bear the weight of 15 elephants. The tensile strength exceeds 1800 megapascals, the elongation exceeds 30%, and the fracture toughness is better than 1/2 of 180 megapascals · m. Compared with the 316LN stainless steel armor widely used in the ITER (International Thermonuclear Experimental Reactor) project, its strength has increased by approximately 40%, while its plasticity and toughness are comparable. That is to say, when subjected to huge mechanical loads, CHSN01 steel is not only as solid as a rock but also possesses astonishing resistance to fracture and deformation.

Meanwhile, CHSN01 steel has driven a lightweight revolution, successfully "slimming down" the superconducting magnet system by 10%. A single device can save 100 tons of structural materials. More importantly, it can significantly improve the operating parameters of the device within a limited space.

Nowadays, CHSN01 steel has passed the most rigorous "practical" test of the Plasma Institute, and its performance comprehensively outperformed international special alloy materials such as 316LN stainless steel and JJ1 used in ITER. At present, CHSN01 steel has been applied in the manufacturing of approximately 300 tons of armor and 200 tons of coil box straight sections in the BEST facility, completing the verification of the world's largest-scale project. This combination of rigidity and flexibility makes CHSN01 steel a strong guardian of the core components of fusion reactors.

In this regard, the technical evaluation report of the Library and Information Center of the Chinese Academy of Sciences stated: "Both China and the National High Magnetic Field Laboratory of the United States have developed materials with a yield strength exceeding 1,500 megapascals at minus 268.95 degrees Celsius. However, only China can simultaneously meet the requirements of an elongation greater than 30% and a fracture toughness greater than 180 megapascals · m ²."

Application Expansion

Innovation across the entire industrial chain forges the "steel and iron backbone" of major national equipment.

Nowadays, CHSN01 steel has established a full industrial chain innovation capability covering "smelting - forming - application", demonstrating broad prospects for application and promotion.

In terms of precise control of smelting, the nuclear fusion Innovation team of Central Iron and Steel Research Institute has innovatively adopted a low-cost smelting process of "electric furnace + argon-oxygen decarburization + ladle refining + electroslag remelting", precisely achieving ultra-low carbon (C≤0.01%) and high nitrogen (N: It features ultra-low impurity control (P≤0.01%, S≤0.005%, Al≤0.02%, O≤0.002%), and a single furnace batch capacity of up to 40 tons, laying a solid foundation for the large-scale batch supply of CHSN01 steel.

In terms of forming manufacturing, the Central Iron and Steel Research Institute, the Institute of Plasma Physics, and Jiuli Special Materials have, for the first time in the world, completed the development of high-strength, low-temperature resistant CHSN01 stainless steel armor for fusion magnets, and it has passed the performance test under real service conditions. In collaboration with Panzhihua Iron and Steel Group's Great Wall Special Steel, Shanghai Electric's Shangzhong Casting and Forging, and Sinomach Heavy Industry's Second Heavy Equipment, they jointly completed the development of a series of CHSN01 hot-rolled plates with thicknesses ranging from 10mm to 90mm and 6-ton large-sized CHSN01 forgings (with thicknesses of 260mm × 560mm × 5000mm). A complete innovation chain has been established, namely "theory of high/medium temperature precipitation phase regulation → extreme manufacturing of high-precision armor/super-large forgings → full-condition verification", which has promoted China's leap from "following" to "leading" in the field of low-temperature structural materials for nuclear fusion.

The picture shows the world's first full-size BEST superconducting magnet with CHSN01 steel as its armor. (Photo provided by Institute of Plasma Physics, Chinese Academy of Sciences)

The picture shows the TF coil box component made of CHSN01 steel in the BEST device, which is the key framework for supporting the superconducting magnet. (Photo provided by Institute of Plasma Physics, Chinese Academy of Sciences)

In terms of application expansion, starting from the first batch supply of 10 tons in January 2024, a batch supply of 100 tons to the BEST facility was achieved within one year. Among them, the CHSN01 stainless steel armor with a total weight of approximately 300 tons has completed the delivery of over 22,588 meters (the total demand is about 52,438 meters), accounting for 43% of the total demand. Three sets of CHSN01 coil box linear section components with a total weight of approximately 200 tons have been successfully delivered (the total demand is 17 sets). Nowadays, its application territory is rapidly expanding from the core components of the BEST device to markets such as aerospace cryogenic storage tanks and hydrogen energy storage and transportation equipment, attracting the attention of international top institutions such as the French Atomic Energy Commission (CEA) and the Karlsruhe Institute of Technology (KIT) in Germany.

The large-scale application of CHSN01 steel is another perfect answer sheet that Chinese steel workers have submitted to the common challenges of mankind. In the future, when the light of the "artificial sun" illuminates human civilization, CHSN01 steel, as the steel backbone that holds up this light, will surely inscribe a glorious chapter of forging a major national equipment in the history of new energy in China and even the world. The giant ship of the clean energy revolution is setting sail from the East.

Email

Email Email

Email