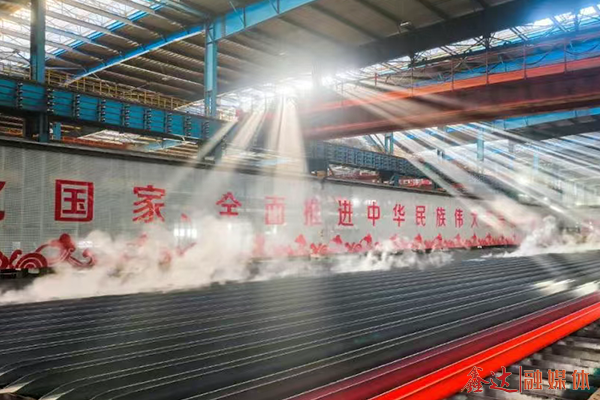

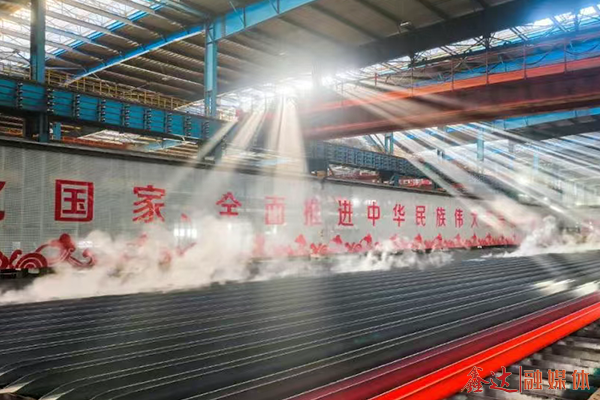

Recently, the Hebei Province Enterprise Management Modernization Innovation Achievement Appraisal Committee awarded the 31st Provincial Enterprise Management Modernization Innovation Achievement Honor Certificate. The "Reducing the Short Length Rate of Section Steel" project of Hebei Xinda Steel Group Co., Ltd. won the "Provincial Enterprise Management Modernization Innovation Achievement Award" for its breakthrough practice in the field of production management. This project focuses on the problem of short length rate in the production of section steel. Through technological innovation and management optimization, it has achieved a dual improvement in economic benefits and production efficiency, providing a typical example for the refined management of the steel industry.

Accurately identify the problem and clarify the direction for tackling it

Hebei Xinda Steel Group, as a large-scale private steel enterprise integrating sintering, ironmaking, steelmaking and steel rolling, has keenly perceived the constraints on the enterprise's benefits and competitiveness caused by the relatively high short-length ratio of section steel. Xinda faced the challenge head-on and established a research team. Through current situation investigation, it was found that the pass rate, hot assembly rate and short length rate were inversely correlated, and the average short length rate of the company was higher than the industry average. Based on this, the target short length rate was set, and problem tree analysis was used to precisely identify the three core factors of "communication between the upper and lower processes, hot assembly rate of steel billet, and maintenance of key and heavy spare parts", and targeted improvement strategies were formulated. Lay a clear path for subsequent breakthroughs.

Innovate and improve strategies to break through production bottlenecks

In response to the core issues, the research team implemented a hierarchical improvement strategy. Process collaborative optimization: Implement a preset mechanism of 0.6 range for the fixed weight difference of billets, covering the production of all specifications of section steel. At the same time, establish a high-frequency billet random inspection system to ensure that the random inspection pass rate of non-conforming billets reaches over 95%, reducing the risk of short lengths from the source.

Production organization innovation: Establish a coordinated production scheduling mechanism between the sales and production departments, introduce a competition model for the hot loading rate of teams, and through target assessment and incentive measures, steadily increase and maintain the hot loading rate of steel billets at over 65%, effectively reducing rolling defects caused by temperature fluctuations.

Equipment support upgrade: Key spare parts such as hook scales have been incorporated into the "one in use and one on standby" key maintenance system. A "Hook Scale Usage and Maintenance Operation Manual" has been formulated. Through standardized operation procedures and regular maintenance, the precision control of equipment has been strengthened to reduce short-length issues caused by equipment failures.

The achievements are remarkable and the demonstration effect is prominent

After the implementation of the improvement measures, the project has achieved remarkable results in multiple dimensions. The core indicators were significantly optimized. The average short-length rate dropped to 0.29%, an increase of 0.35% compared to before the event, and the annual benefit reached 1.764 million yuan. Management innovation and technological breakthroughs: During the project implementation process, a utility model patent for "A Steel Stacking Prevention Device for Rolling Mills" was successfully applied for. At the same time, the "Operation Manual for the Use and Maintenance of Hook Scales" was revised to form a standardized management process, consolidating the achievements while enhancing the process standardization. The industry promotion and demonstration effect: This achievement has been applied and promoted in the Steel Rolling General Plant of Hebei Xinda Steel Group and the Section Steel Plant of Jilin Xinda Steel. By replicating the management model of "fixed weight preset - hot installation lifting - equipment maintenance and repair", the short-length rate has been effectively reduced, and the internal management experience sharing within the group has been achieved.

After years of promoting innovation work, Hebei Xinda Steel Group has established a "full-chain innovation management system" and formed a unique innovation work model. At the level of establishing an innovation mechanism, a collaborative innovation platform of "industry-university-research-application" should be established, and joint research and development should be carried out with universities and research institutions to address common problems in the industry. At the same time, an innovation special fund will be established to offer special rewards to teams and individuals who put forward innovative suggestions and achieve results, thereby stimulating the innovation vitality of all staff.

In terms of digital innovation and integration, accelerate the digital transformation of the production process, introduce an intelligent monitoring system to collect and analyze real-time data throughout the entire process of steel section production, and accurately predict short-length risk points through big data modeling. Build an intelligent platform to integrate multi-dimensional data such as production, quality and equipment, achieve intelligent and visual management decisions, and provide data support for the dynamic adjustment of innovation strategies.

In terms of the talent cultivation mechanism, the "Innovative Talent Echelon Construction Plan" has been implemented. Through diversified training methods such as the internal mentorship system, external expert lectures, and further education for key personnel, a compound innovative talent team covering technology research and development, production management, and equipment maintenance has been built. Regularly organize innovation achievement sharing sessions and skills competitions to foster an innovative cultural atmosphere of "learning from each other and striving for excellence", continuously injecting talent impetus into the enterprise's innovation.

Honor testifies to strength; forge ahead and embark on a new journey. The Hebei Provincial Enterprise Management Modernization Innovation Achievement Award is a high recognition of Xinda's production management innovation capabilities. As a leading enterprise in the steel industry, Xinda will continue to adhere to the principle of "innovation-driven and lean management", deepen the practice of "reducing consumption and tapping potential", focus on production pain points, and explore more replicable management innovation models. In the future, the company will continue to increase investment in technological innovation and digital transformation, contribute more "Xinda Solutions" to the green and intelligent development of the steel industry, and promote the industry to move towards higher quality and higher efficiency!

Email

Email Email

Email